| brandABB | todateLong-term effective | 最后更新2025-03-13 14:25 |

| hits3 |

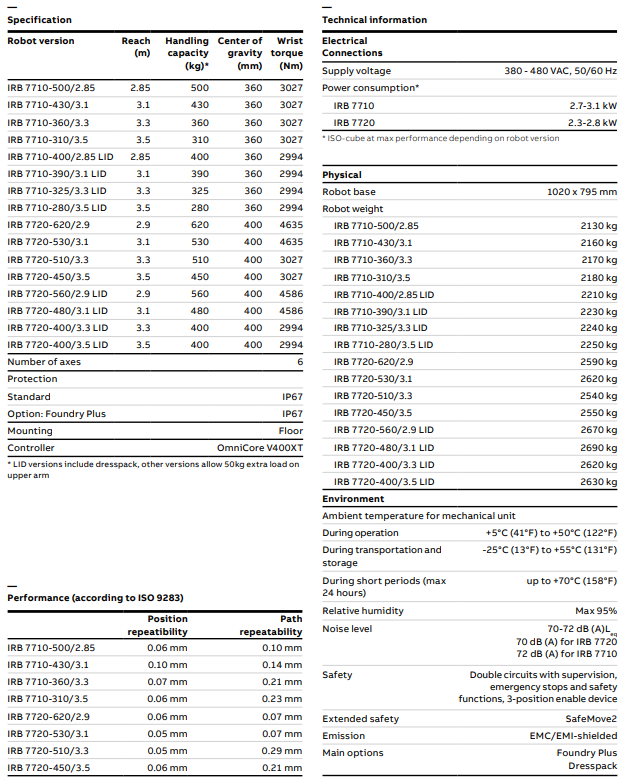

ABB Multi-joint Robot IRB 7710-430/2.85 LID Load 430kg Arm Span 2850mm

Key benefits

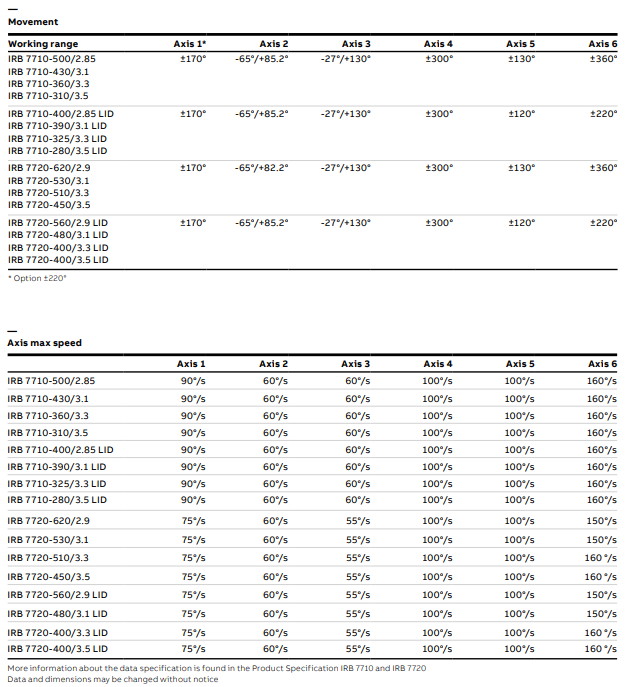

1. Productivity: robots achieve class-leading motion control with path accuracy down to 0.6mm at high speeds of up to 1600mm/s.

2. Flexibility: 16 different variants empower customers to select the ideal robot for various applications.

3. Energy savings: IRB 7710 combined with OmniCore has 30% less energy consumption1.

4. Uptime: LeanID DressPack eliminates swinging cables and supports off-line programming to enhance uptime.

Greater flexibility and choice

As manufacturers ramp up production, they can choose from a wide range of ABB robots to ensure they have the right variant to handle various applications across a wide range of industries such as automotive, agriculture machinery, construction, and logistics, as well as mega casting in the foundry industry.

Unmatched productivity and quality

Powered by OmniCore V400XT, the IRB 7710 and IRB 7720 achieve class-leading motion control with path accuracy down to 0.6mm, even with multiple robots running at high speeds of up to 1600mm/s and moving payloads of up to 450kg. Customers can also benefit from an up to 25% reduction in cycle times1 further enhancing productivity and quality.

Energy savings by up to 30%

Helping customers operate more sustainably, IRB 7710 combined with OmniCore has 30%1 less energy consumption. This is achieved by the robot’s efficient design and the OmniCore™ energy regeneration technology and built-in power pack can relay energy back to the grid.

Efficient modular design

These large robots are based on the same groundbreaking modular design, with standardized components across all large robot platforms, including the base, lower arm, and upper arm. All of the robots now have the same footprint, enabling faster, more convenient, and more flexible installation when changing robots in different production lines.

Target industries: automotive, agriculture machinery, construction, logistics, and foundry.

Target applications

1. High-payload assembly and handling, such as EV batteries, foundry parts, or cabins for the above mentioned industries.

2. High-speed press tending and palletizing, such as car doors, frames, boxes, and pallets.

3. High-precision and stiffness contact applications, such as friction stir welding for battery trays, machining.

CSH:

CSH:

&tel=&work=15858332723&email=ffffiona2024@163.com&org=ABB robot service provider in China&adr=38 Tingyao East Road, Jiashan County, Jiaxing City, Zhejiang Province, China&url=http://www.bogangzhineng.com/com/bg-abbrobot/)

[Section1year] exponent:1

[Section1year] exponent:1