| brandABB | todateLong-term effective | 最后更新2025-03-03 15:37 |

| hits2 |

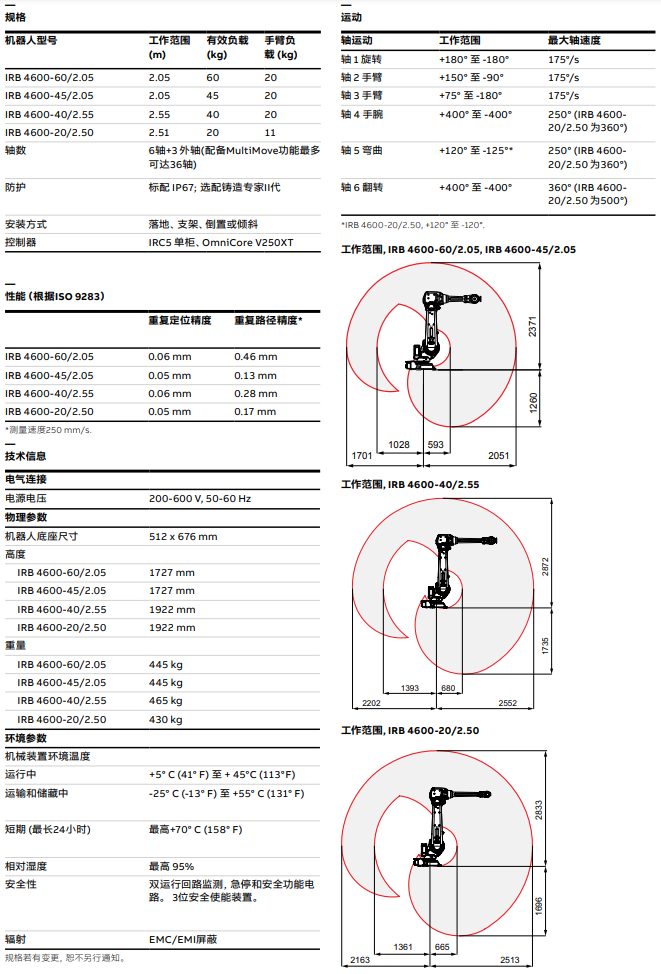

ABB Multi-joint Robot IRB 4600-60/2.05 Load 60kg Arm Span 2050mm

To short

The IRB 4600 features an innovative and optimized design, compact and lightweight, with the highest acceleration in its class in ABB, combined with its ultra-fast operating speed, which reduces cycle times by as little as 25% compared to industry standards. In operation, the robot can always maintain maximum acceleration while avoiding obstacles and following paths, thereby increasing productivity and efficiency.

Oversized range

The IRB 4600's large working range enables comprehensive optimization of reach distance, cycle time, auxiliary equipment, etc. The robot can be flexibly installed in landing, oblique, half-stand, and inverted, which provides great convenience for simulating the optimal process layout.

Slim fuselage

The IRB 4600's small footprint, short axis 1 transposition radius, slim elbows behind axis 3, small upper and lower arms, and compact wrists make it the slimmest robot in its class from ABB. By using the IRB 4600, you can create a production unit with robots closer to the service machines and a smaller footprint, increasing throughput and production efficiency.

well-protected

ABB's industry-leading product protection program further strengthens the IRB 4600's protective safeguards. The Foundry Plus system meets IP 67 protection standards and also includes corrosion resistant coating, rust-proof mounting flange, molten metal spatter protection for the rear fixed cable of the robot, and a protective cover for the cable interface of the foot floor.

Performance optimization

To get the most out of the IRB 4600, you have access to a range of high-performance job positioners, motion tracking, motors, and gear sets. To simulate your production unit, find the best place for your robots and program them offline, you can subscribe to RobotStudio, which can be used for multiple applications and PowerPacs.

Main applications:

Arc welding

Fit out

Material handling

Loading and unloading

Material removal

Cleaning/spraying

gumming

package

Laser cutting

Laser welding

CSH:

CSH:

&tel=&work=15858332723&email=ffffiona2024@163.com&org=ABB robot service provider in China&adr=38 Tingyao East Road, Jiashan County, Jiaxing City, Zhejiang Province, China&url=http://www.bogangzhineng.com/com/bg-abbrobot/)

[Section1year] exponent:1

[Section1year] exponent:1