KUKA Friction Stir Welding is an advanced welding technique that has many advantages compared to traditional welding methods.

For example, no welding materials need to be added during the welding process, and the welded joint has high strength, low residual stress,

and small welding deformation, which have wide applications in many fields.

Firstly, KUKA friction stir welding has important applications in the field of automobile manufacturing, especially in the welding of battery trays for electric vehicles.

Automobiles are an indispensable means of transportation in modern society, with very high requirements for welding technology.

KUKA friction stir welding can stably and reliably connect automotive components, not only with excellent welding quality, but also with very fast welding speed,

which can greatly improve production efficiency. In addition, friction stir welding can effectively reduce the thermal deformation and stress concentration generated during the welding process, and improve the strength and durability of the welded joint.

Therefore, KUKA friction stir welding will have more applications in the field of automotive manufacturing.

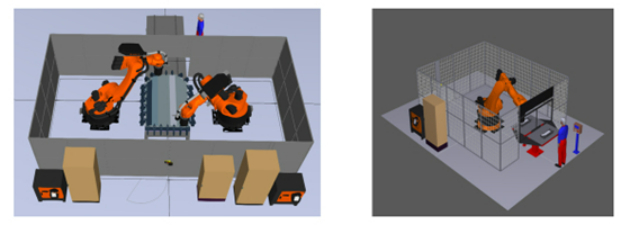

The robot assisted friction stir welding (FSW) technology of KUKA FSW application module, combined with KUKA's cell4_SW, not only elevates the production process to a whole new level in terms of quality, but also in terms of economic benefits and environmental protection.

Secondly, compared to other friction stir welding methods, robot based 3D welding seam motion also has good and wide application extension.

By controlling the robot, welding can be achieved on curved surfaces, resulting in more precise welding effects. In addition, compared to other solutions,

the robot friction stir welding unit occupies a smaller area and can be flexibly combined to achieve significant efficiency improvements, enabling it to cope with future capacity expansion with ease.

In addition, friction stir welding can also achieve welding of complex shaped components, such as aircraft wings.

Therefore, the application prospects of KUKA friction stir welding in the aerospace field are very broad.

In addition, KUKA friction stir welding has gradually been applied in fields such as military equipment manufacturing, railway vehicle manufacturing, energy, and machinery manufacturing.

In the field of military equipment manufacturing, the strength and reliability of welded joints are crucial for the safety of military equipment, and KUKA friction stir welding can meet this demand.

In the field of railway vehicle manufacturing, KUKA friction stir welding can achieve high-strength welding of rail vehicles, improving their durability and safety.

In the field of energy, friction stir welding can achieve welding of high-temperature materials such as gas turbine blades, improving the efficiency and reliability of energy equipment.

In the field of mechanical manufacturing, KUKA friction stir welding can achieve efficient and high-quality welding of complex components, improving overall production efficiency.

With the continuous development and improvement of technology, it is believed that KUKA friction stir welding will demonstrate greater potential and application value in more fields.