KUKA has launched a control cabinet renovation plan, which provides customers with KR C2 upgrade and KR C4 control cabinet upgrade services. In addition, the QUANTEC-2 series and FORTEC series support upgrades from KR C4 to KR C5.

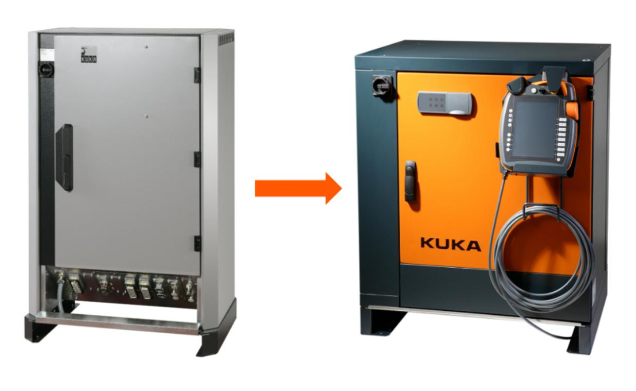

Upgrading KR C2 control cabinet to KR C4 control cabinet

Scope of renovation

Upgrade and replace the original control cabinet with KR C4 control cabinet

Internal piping package for robots

Connection cable between control cabinet and robot

Upgrade the original button based teaching pendant to a touch based teaching pendant

Upgrade the communication and process software package for system requirements to the supported C4 version

Upgrade advantages

The original KR C2 entity can be reused to avoid idle assets

Reduce downtime caused by aging of electrical appliances and circuits, etc

The upgraded touch teaching pendant is easier and more convenient to operate, making it easy for operators to get started and use

Compared to replacing the entire set of robots, upgrading only the control cabinet saves a lot of debugging time, which reduces the limited production time of the product

While retaining the original KR C2 body, there is no need to replace the tools and process pipeline packages currently in use.

The KR C2 control cabinet has been discontinued since 2012, and spare parts supply for KR C2 will no longer be guaranteed after 2022.

Upgrading to KR C4 control cabinet can effectively avoid the risks of spare parts shortage and long-term downtime caused by hardware damage to KR C2 control cabinet, and to some extent reduce equipment maintenance costs

The KR C4 control cabinet can be upgraded in conjunction with the entire line, and its control system has more interface and communication options, making it more scalable compared to the KR C2 control cabinet

In the context of rapid technological development, technological innovation and product iteration are constantly emerging.

KUKA adheres to the principle of innovation and always follows the laws of the market, making its products more and more in line with the needs of the market and customers.

In modern industrial production, robot control cabinets play the role of the brain, and their performance directly affects the efficiency and stability of the entire production line.

On this basis, this issue's news will provide a detailed introduction around the comprehensive renovation of the control cabinet.

The KR C2 control cabinet ceased production in 2012, and after years of use, the lifespan of its circuit components is nearing its end. The aging of electrical components in the control cabinet under long-term use is inevitable, but the robot body adapted to KR C2 is still durable. To economically and effectively solve the problem of aging control cabinet appliances, KUKA has launched a control cabinet renewal plan, which provides customers with KR C2 upgrade and KR C4 control cabinet upgrade services. The service aims to preserve the main body, and the upgrade plan for the control cabinet will to some extent avoid the risks of downtime and daily maintenance caused by electrical aging. In addition, the replaced control cabinet will also update the system, allowing customers to use the updated system and related functions.

Applicable models

Partial KR 2000 series

KR 360/KR 500 series

KR 16 series

KR 30/60 series, etc