Service product content

Robot maintenance and upkeep content

Basic testing (once/5000H or once/year)

Take photos of the robot's appearance before maintenance to confirm any stains or dirt

document backup, including fault logs, and diagnostic document backup if necessary

Detection of abnormal noise in motion robots (pipeline package, motor, gearbox balance cylinder)

Check the safety circuit emergency stop and related safety equipment

Check the connectors (body and control cabinet)

Tension detection and adjustment of transmission belt (if there is a transmission belt)

Check the usage of the teaching pendant (appearance, screen, buttons, nameplate, etc.)

Detect battery voltage and power supply system voltage

Central Hand Maintenance (once/5000H or once/year)

Take photos of the robot's appearance before maintenance to confirm the degree of contamination

document backup, including fault logs, and diagnostic document backup if necessary

Detection of abnormal noise in motion robots (pipeline package, motor, gearbox balance cylinder)

Check the degree of wear on the pipeline package and whether the cables are damaged, deformed, or subjected to stress

Zero point inspection, photo recording

Gas liquid equilibrium system detection (if there is a gas liquid equilibrium system)

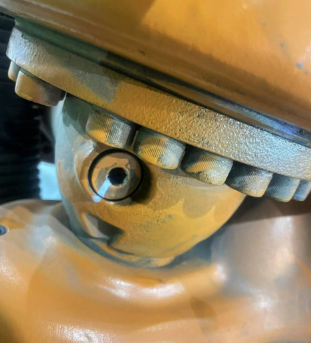

Check the A1-A6 gearbox for oil leakage and damage, take photos and archive them

4th, 5th, and 6th axis gearbox oil change

Drive belt replacement and tension adjustment

Fill in maintenance records for the teaching pendant

Check the sealing of the control cabinet and the fan

Key point lubrication

Fill in maintenance records for the teaching pendant

Spindle maintenance (once per 10000 hours or once per 2 years)

Oil change for 1st, 2nd, and 3rd axle transmissions

Replacement and tension adjustment of the third axis drive center manual transmission belt

Fill in maintenance records for the teaching pendant

Maintenance and upkeep of control cabinet

Primary electrical maintenance (once/5000H or once/year)

Control cabinet inspection

Clean the heat exchanger

Clean the cooling elements of the drive components

Clean the external fan

Replace the battery

Fill in maintenance records for the teaching pendant

Advanced electrical maintenance (once per 10000 hours or once per 2 years)

Control cabinet inspection

Replace the constant pressure filter cotton in the control cabinet

Replace PC fan and internal fan

Replace the external fan

Replace the motherboard batter

Clean the control cabinet

Fill in maintenance records for the teaching pendant

Maintenance classification

Basic maintenance: including basic inspection/center hand maintenance/spindle maintenance/primary electrical maintenance

Advanced maintenance: including basic inspection/central manual maintenance/spindle maintenance/primary electrical maintenance/advanced electrical maintenance