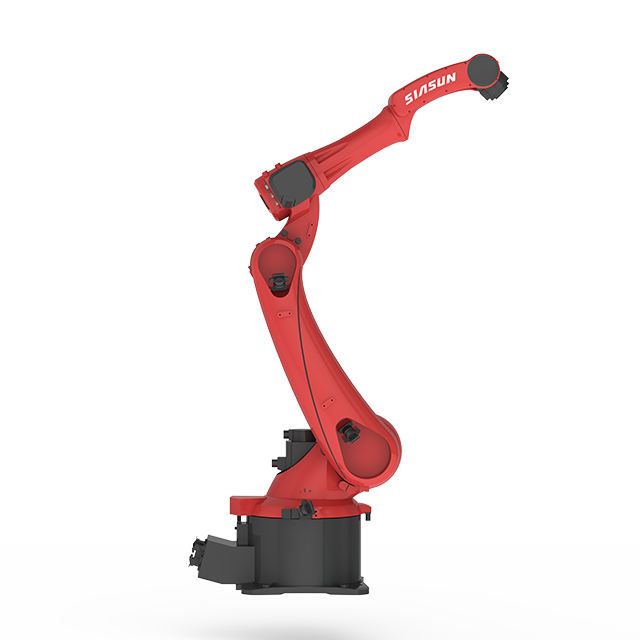

Siasun SR25A-12/2.01 robot adopts a streamlined hollow arch arm design to significantly reduce workpiece interference, optimize operational flexibility and layout compact. The built-in welding cable system effectively avoids external wear and enhances wire feed stability and the universality of welding operations. The model supports a variety of installation modes, ADAPTS to confined space operation, and enables a wide range of heavy machinery, shipbuilding, automobile manufacturing, rail vehicles and many industrial fields.

With its high stiffness, lightweight structure and powerful drive system, the SR25A-12/2.01 achieves a double leap in speed and accuracy, and its balanced configuration and superior cost performance ensure stable and reliable operation. With its innovative design and excellent performance, the robot has set a new benchmark in the field of small-load robot applications, demonstrating market leadership.

Product advantage:

1.Flexible deployment:

The hollow arm design effectively reduces the interference with the workpiece, improves the working flexibility in complex environments, and ensures that the robot can achieve the best working attitude in a limited space

2.Accurate and efficient:

Excellent power performance, can meet the rapid production rhythm of high precision, high speed and high stability requirements, adapt to a variety of harsh production conditions

3.Lightweight design:

Using a special casting process of aluminum alloy for automotive engines, the lightweight fuselage is combined with a strong driving force to achieve extreme speed and accuracy

4.Extraordinary intelligence:

Advanced intelligent control system, easy to maintain and manage

Product parameter:

Rated load :12kg

Working range :2010mm

Number of control axes :6

Repeated positioning accuracy :±0.07mm

Installation method: formal installation, inverted installation

Protection level (wrist) :IP65