ABB is expanding its large size robot portfolio withIRB 5710, offering faster performance, more accurate, expanded mounting options, and advanced foundry protection than other competing robots in its class. The IRB 5710 is available in four variants spanning various options for payload from 70kg to 110kg, reach from 2.3m to 2.7m.

IRB 5710 is ideal for use in material handling, machine tending, and high precision assembly applications in the Electric Vehicle (EV), automotive, and the general industries. For Electric Vehicles, robots can handle an array of tasks, including EV battery module picking and placing, high precision assembly, and parts handling. For general industries, the robots can be used for a wide range of tasks in die casting, material removal, cleaning, spraying, and general high precision applications.

Productivity

Thanks to the robot’s robust mechanical design and OmniCore controller V250XT’s motion control, the IRB 5710 provides improved speed and accuracy to help increase productivity. IRB 5710 is faster than competing robots and up to 25 percent faster than ABB’s large-size robots (IRB 6700 and IRB 6620), enabling more products to be manufactured in less time. With the excellent position repeatability, path accuracy, and path speed, IRB 5710 is more accurate than other robots, enabling the highest levels of manufacturing quality to be achieved.

LeanID Integrated DressPack increases uptime

By integrating cabling within the body of the robot, ABB’s unique LeanID Integrated DressPack reduces the problem of swinging cables that can cause wear and tear, reducing downtime and maintenance cost. LeanID makes it easier to program and simulate with predictable cable movements at RobotStudio.

Flexible production layout

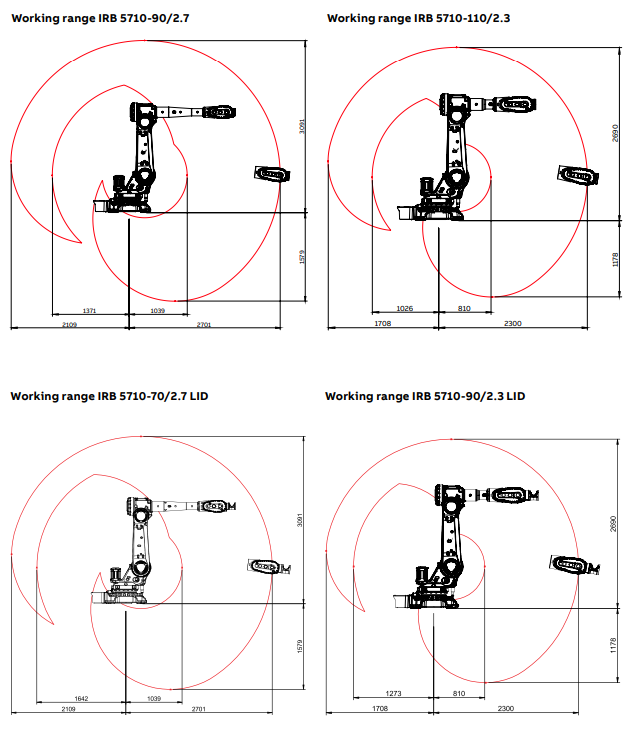

IRB 5710 has multiple mounting options, including floor, angled, inverted and semi shelf for maximum production layout design flexibility. IRB 5710 offers more mounting options than other robots.

Foundry protections

The robots also include superior harsh environment protection, Foundry Plus, additional sealant protection for high radiant or contact heat, ensuring higher availability, fewer breakdowns and longer equipment lifetime. The optional protection guards IRB 5710 against the harshest of foundry environments.

Key benefits

• TrueMove and QuickMove software enables bestin-class motion control and improved cycle times, and path accuracy.

• Increased speed and shorter cycle times – faster than other robots, and up to 25 percent faster than IRB 6620 and IRB 6700.

• LeanID Integrated DressPack reduces cable wear and tear, and lengthens service interval.

• Robust design with a rigid structure increases uptime.

• Multiple mounting options for flexible production layouts.

• Built to operate in harsh environments—available with Foundry Plus protection.

Main applications

• EV Battery modules picking, placing, and high precision assembly.

• Automotive tier 1 parts material handling, and machine tending.

• General Industry material handling, machine tending, die casting, and general high precision applications.