Beat shortening

IRB 2600ID All process lines are embedded in the robotic arm, significantly reducing the risk of downtime due to interference and wear. This integrated design also ensures that operating acceleration is always unconditionally maximized, resulting in significantly shorter beat times and increased production reliability.

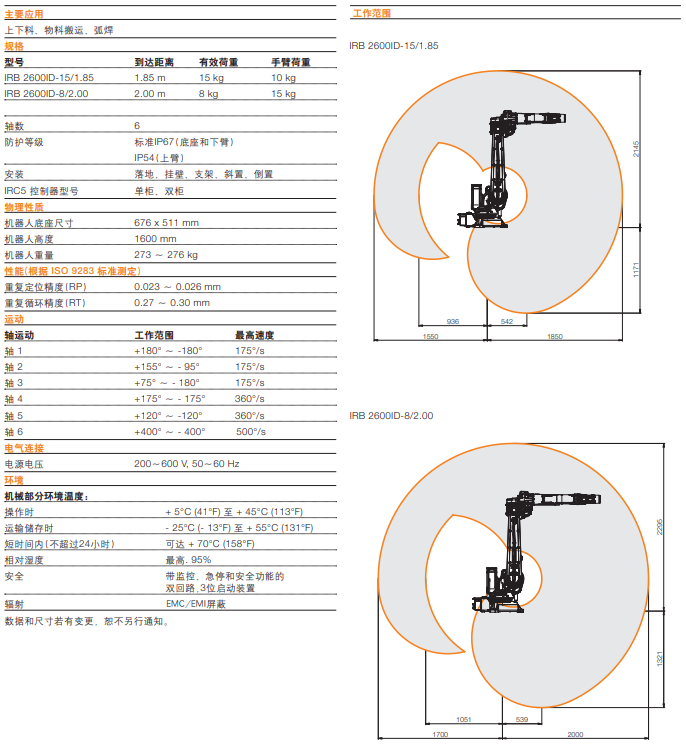

The IRB 2600ID series comes in two models. One has a reach distance of 2.00m and a load of 8kg, which is suitable for integrated arc welding process equipment; the other has a reach distance of 1.85m and a load of 15kg, equipped with flexible wiring harness, which is good at material handling and loading and unloading operations

Speed up programming

Hollow arm (ID) technology further enhances the convenience of offline programming. The pipeline movement is controllable and easy to predict, so that the programming and simulation can accurately preview the operating state of the robot system, greatly shorten the program debugging time, and accelerate the production schedule. Save up to 90% of programming time from start to finish.

Reduce investment costs

All IRB 2600ID lines are properly fastened and protected, which not only reduces the swing during operation, but also effectively protects against welding splash and cutting fluid erosion, significantly extending the service life. Procurement and replacement costs can be reduced by up to 75%, and up to three downtime repairs per year can be reduced.

Save space, increase capacity

The IRB 2600ID has a compact design, no loose lines, and a very small footprint with a transposition radius of only 337 mm and a base width of only 511 mm. In material handling and loading and unloading operations, the robot can be closer to the supporting mechanical equipment. In arc welding applications, these design advantages reduce the risk of interference with other robots, creating favorable conditions for high-density, high-throughput operations. With the same production workstation, the number of IRB2600ID installations can be increased by 50%, and the production capacity can be increased by up to 50%. In short, the IRB2600ID maximizes the benefit of production space, contributing more output with a smaller footprint,

Work well in tight Spaces

The IRB 2600ID has an unusually slim wrist, measuring just 227x130 mm. All pipelines are integrated into the robot's craft wrist, allowing complex actions to be performed even in confined Spaces. In arc welding, for example, the IRB2600ID can perform high-quality ring welding in a shorter beat time, achieving a significant increase in production.