Major advantage

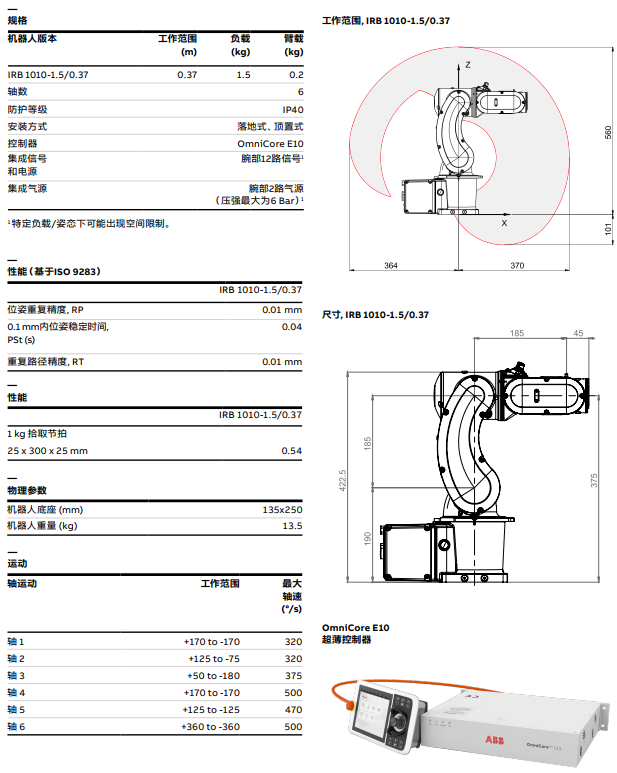

ABB's smallest industrial robot:

With a 30% smaller footprint *, the IRB 1010 can be installed in tight production Spaces and can also be used as part of a dedicated machine, which is particularly suitable for high-density production layouts and increases productivity by making full use of available space.

High load results in high efficiency:

With an industry-leading 1.5kg load, the IRB 1010 can handle more product in the same amount of time, resulting in increased yield and efficiency.

6-axis braking system reduces downtime:

The IRB 1010 is equipped with a 6-axis braking system that stays in place during power outage or suspension, eliminating reset time and enabling a quick return to production and increased productivity.

Outstanding precision performance:

Repeatable positioning and path accuracy of 0.01mm ensures high precision and high quality production.

Equipped with omnicore controller:

The OmniCore E10 ultra-thin controller provides outstanding motion control and energy savings of up to 20% compared to the ABBIRC5C controller. Built-in digital connectivity and more than 1,000 additional features enable the Omnicore E10 to meet the changing customer needs of the future with superior motion control for leading repeatable precision performance.

Stronger vacuum suction, higher handling efficiency:

The larger diameter upper arm air hose (4mmx2) provides greater vacuum suction, allowing the IRB 1010 to carry more items at the same time and achieve higher productivity than other comparable products.

Robot Control Mate makes programming easier:

Users can easily control the motion of the IRB 1010 robot by moving, teaching or calibrating the IRB 1010 robot in real time through smart devices such as computers or tablets.