ABB's industrial robots have a wide range of auxiliary equipment that can enhance the robot's function, improve its efficiency and accuracy. Here are some common ABB industrial robot auxiliary equipment:

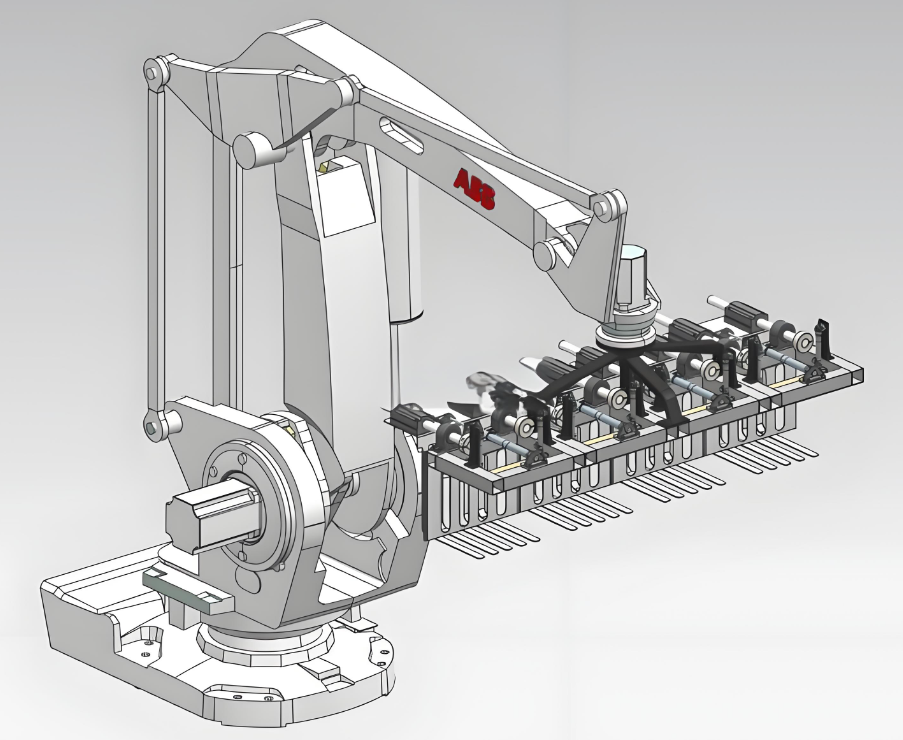

1. fixture: fixture is a commonly used auxiliary equipment for industrial robots, used to fix the workpiece, so that the robot can process the workpiece, assembly and other operations. The design of the fixture is usually customized according to the shape, size and processing needs of the workpiece to ensure the stability and accuracy of the workpiece during processing.

2. Sensor: Sensor is one of the key auxiliary equipment of industrial robots, which can help robots perceive the environment, master their own state, and achieve more accurate operation. Commonly used sensors include photoelectric sensors, pressure sensors, force sensors, etc., which can measure the position, shape, quality and other information of the workpiece, thereby helping the robot to adjust and operate according to needs.

3. Welding power supply: In the welding workstation, welding power supply is an indispensable auxiliary equipment. ABB industrial robots can be used with a variety of welding power sources, including domestic, Japanese and European and American welding power sources, to meet different welding needs.

4. Auxiliary positioner: auxiliary positioner is used to change the position or attitude of the workpiece, so that the robot can be more convenient for processing or assembly. Common auxiliary positioner include single-axis reversing positioner, two-axis positioner, etc. These devices can be customized according to the shape of the workpiece and processing needs.

5. Vision system: The vision system is one of the commonly used auxiliary equipment of industrial robots, which can help the robot to identify the characteristics and position of the workpiece, so as to achieve automatic processing, assembly and other operations. Vision systems typically include components such as cameras and image processors that can image, process, and recognize artifacts.

6. Electrical control equipment: Electrical control equipment is an important part of ABB industrial robot system, including PLC controller, frequency converter, main operating panel, robot control system, etc. These devices are responsible for controlling the robot's movement, processing parameters, and working with other devices to ensure the stable operation of the entire system.

7. Safety guardrail: Safety guardrail is the necessary equipment to ensure the safe operation of the robot system. It prevents people from straying into the robot's work area, thereby avoiding potential safety risks. At the same time, the safety guardrail can also play a role in isolating noise and reducing dust pollution.

In addition, depending on the specific application needs, ABB industrial robot auxiliary equipment may also include pallet distributor, pallet stacker, pallet conveyor, shuttle, automatic guided vehicle (AGV) and other logistics equipment, as well as labeling machine, stretch packaging machine and other packaging equipment. These devices can further improve the level of automation and production efficiency of robotic systems.

ABB industrial robots have a wide range of auxiliary equipment with different functions. The selection of suitable auxiliary equipment is very important to improve the overall performance and efficiency of the robot system.